https://en.wikipedia.org/wiki/Theory_of_constraints

In 1984, Management Expert, Eliyahu M. Goldratt published ‘The Goal’. A novel that introduced the theory of constraints within a manufacturing business. The logic behind the theory is that every system/lifecycle will develop a bottleneck at some point in time which impedes flow. The objective of management is to identify the bottleneck, resolve it as quickly as possible, and drive improvement thus increasing flow.

The Theory of Constraints is based on the premise that the rate of goal achievement (by a system) is limited by at least one constraint.

- Example goals: revenue, throughput, cost, quality etc

- Example constraints: time, resource, quality, inefficiencies, waste etc

Assuming the goal of a system has been articulated and its measurements defined, the five focusing steps are:

- Identify the constraint (what is the weakest link in the system?)

- Optimise the constraint (what is the maximum performance?)

- Subordinate the non-constraints (regulate flow according to the constraint)

- Improve the system’s constraint

- Identify the next constraint

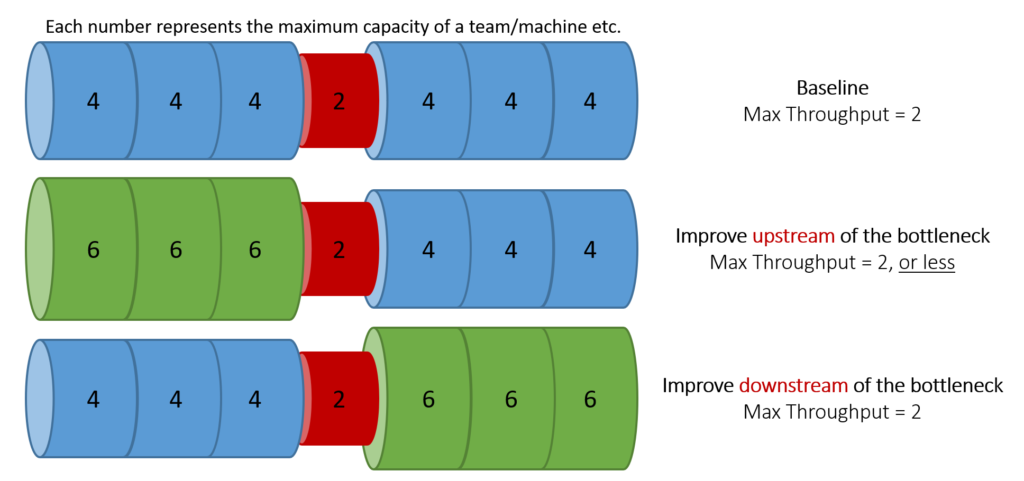

In a typical corporate setting. All functional siloes are asking for more money to drive improvements. Whether through increasing the number of resources, or implementing automation. However, depending upon where improvements are made, you might not see a benefit overall. And, in some cases, overall throughput may end up worse.

Locally you can always expect to see an improvement. For example, if the first team adopts SCRUM. Within that team, throughput may increase.

Unfortunately, if that team was not the bottleneck, then we may not see more releases into production. I.e.

- If you improve upstream of a bottleneck, you will not see an increase in overall throughput, and sometimes throughput will reduce as more strain is added to the constraint

- If you improve downstream of a bottleneck, you will have idle capacity